The advantages of the three-cylinder engine Naturally a […]

The advantages of the three-cylinder engine

Naturally aspirated has become history, and major manufacturers are squeezing the potential of turbocharging. From large-displacement naturally aspirated to small-displacement turbocharging, although a little fuel consumption that can be reduced may not necessarily make consumers much interested, but under the guidance of policies, car manufacturers have to do it. Three-cylinder engines are more environmentally friendly than four-cylinder engines. In response to the national call, major car companies have launched new energy strategies. In 2020, there will be more and more blue actions to reach the average fuel consumption limit of 5 liters per 100 kilometers. Manufacturers use three cylinders as car engines.

The performance of the naturally aspirated engine in terms of fuel consumption and power is already inferior to that of the three-cylinder small-displacement turbocharged engine. The main advantage of the three-cylinder engine is fuel economy! The three-cylinder engine with turbo technology is more powerful and more fuel-efficient than the four-cylinder engine. Low cost: One less cylinder means one less spark plug, one piston, one connecting rod, one set of valves, etc. The fewer parts, the lower the cost of the entire engine. Small power loss: One less cylinder, first of all, one less set of pistons and connecting rods, and one less set of valves. The fewer components running inside the engine, the less power loss. Secondly, when the engine is running, the piston will continuously rub against the cylinder and lose a part of the power; reducing the cylinder will reduce the total surface area of the cylinder, thereby reducing the power lost due to friction. The smaller the internal loss of the engine, the better the fuel consumption and power will be.

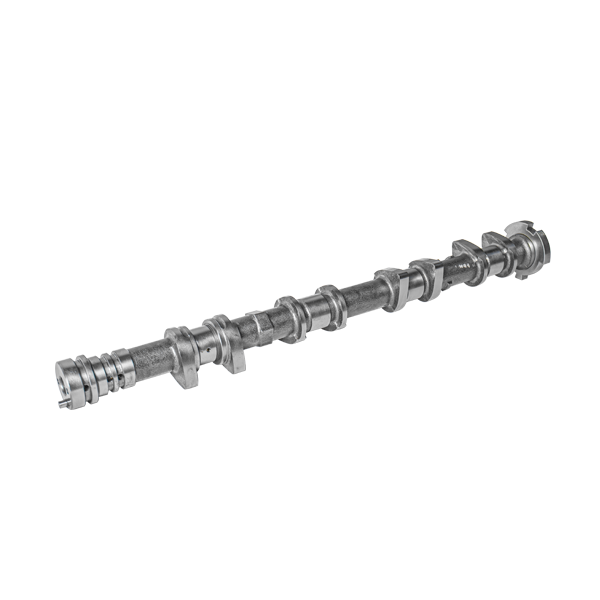

1. The shaft body and the shaft head are not integrated by welding, but are formed by warm extrusion. The metal fibers of the shaft body are streamlined and not damaged, thereby increasing the strength of the shaft body and making the appearance more comfortable;

2. After the overall heat treatment of the shaft body, the grain size level reaches 8-7, which is basically in an ideal state;

3. Compared with other axles of the same tonnage, the axle is light in weight, large in load, and the dynamic load coefficient is greater than 2.5, which is more economical and applicable;

4. Due to the use of Custom Cold shock camshaft blank non-asbestos friction plates, it does not pollute the environment and is more environmentally friendly;

5. Due to the use of international common spare parts, the use is more convenient, faster, more economical, and more suitable for the needs of guests.

The upstream impact on the auto parts industry is mainly in terms of cost, and changes in the prices of raw materials (including steel, aluminum, plastic, rubber, etc.) are directly related to the manufacturing cost of auto parts products. The downstream impact on auto parts is mainly in terms of market demand and market competition. With the development of science and technology, the replacement of automobile products is accelerating, which requires the auto parts industry to speed up technological innovation and provide products that are in demand in the market; otherwise, it will face the dilemma of supply and demand disconnection, resulting in structural imbalance and product backlog. .

The upstream of the auto parts manufacturing industry chain mainly includes markets that provide raw materials, including steel, non-ferrous metals, electronic components, plastics, rubber, wood, glass, ceramics, leather, etc.

Zhejiang Junrong Auto Parts Co., Ltd.