The following camshaft wholesale, camshaft manufacturer […]

The following camshaft wholesale, camshaft manufacturers and camshaft brand companies will talk about the broken camshaft adjuster, which may cause the following problems:

1. The car has high pressure fire, but the starting time is long, and the car can finally run;

2. During the starting process, the crankshaft will be reversed, and the intake manifold will be backfired;

3. The idling speed is unstable and the vibration is serious, similar to the failure of a car lacking cylinder;

4. The car is weak in acceleration and the car cannot run. It will be better if the speed exceeds 2500 rpm;

5. There will be high fuel consumption, excessive exhaust emissions, and unpleasant black smoke emissions from the exhaust pipe.

How to check and adjust the camshaft axial clearance?

The following camshaft wholesale, camshaft manufacturers and camshaft brand companies talk about how to check and adjust the camshaft axial clearance?

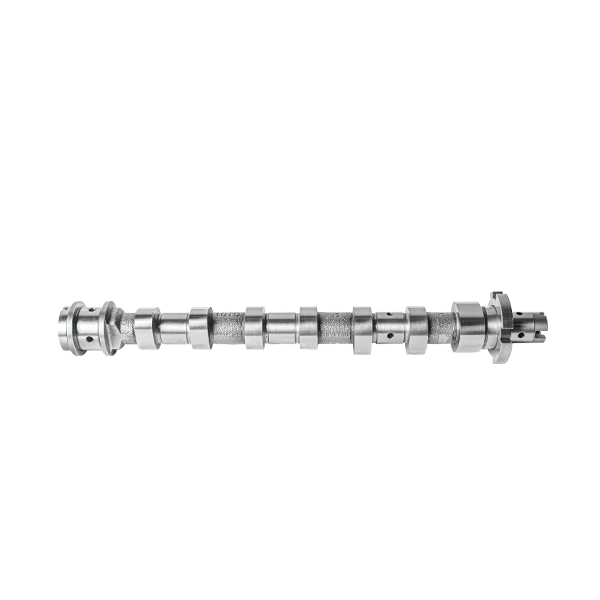

The axial clearance of the camshaft of Custom 4-cylinder dual VVT camshaft an automobile engine is determined by the thickness difference between the thrust plate (thrust flange) and the spacer. The gaps are all 0.10~0.20mm, and the maximum shall not exceed 0.30mm.

The thickness difference between the thrust plate and the spacer can be directly measured during inspection. If the engine assembly is not disassembled, when checking the axial clearance of the camshaft, remove the timing gear cover and the side cover of the gear chamber, pry the camshaft forward, and then check with a thickness gauge.

When the axial clearance of the camshaft is too large, replace the thrust plate to adjust it. When adjusting, it should be noted that the thickness of the spacer should meet the requirements and cannot be arbitrarily thinned, otherwise the axial position of the camshaft will be changed and the accuracy of the valve phase will be affected.

How does a bad camshaft sensor affect the car?

1. It will make it difficult to start the engine, or the ECU cannot obtain the information fed back by the sensor, resulting in abnormal control of the engine's intake and exhaust system and affecting its performance;

2. The crankshaft is reversed when the car is started, resulting in the problem of backfire of the intake manifold;

3. The ECU cannot obtain information, and there is a problem of disordered fuel injection, which leads to an increase in fuel consumption;

4. The vehicle will vibrate seriously. The solution to the broken camshaft sensor: the camshaft sensor of the car needs to be repaired, and a new sensor needs to be replaced if necessary.

Brake camshaft is an important component of automobile brake parts, and its surface is required to have high hardness and wear resistance, and at the same time, the core must have certain toughness to meet high fatigue strength requirements. In order to meet these requirements, a comprehensive design has been carried out in terms of inductor structure, power supply parameters, heating methods and cooling methods. The results show that this quenching process completely meets the requirements of the camshaft quenching process. The following camshaft wholesale, camshaft manufacturers and camshaft brand companies will introduce the induction hardening process of automobile brake camshafts in detail.

Quenching Process Requirements Overview

The material of the brake camshaft used in the experiment is 45 steel, the shaft diameter is 40mm, the quenching technical requirements are the surface hardness of 52~63HRC, the depth of the hardened layer of the shaft is 2~3.5mm, and the depth of the hardened layer of the peach tip is less than 10mm.

The automobile brake camshaft is mainly composed of a core part, a shaft part and a spline, of which the core part and the spline are profile quenched, and there are special requirements for the quenching process.

Zhejiang Junrong Auto Parts Co., Ltd.